We have finally started construction on my son and daughter-in-law’s house in Pennsylvania. Greg, Dan, and Anna have been slogging through the design and permitting process which I have managed to avoid. Bucks County, PA has rigorous permit requirements and requires that all plumbing, HVAC, insulation, and drainage designs are in place and approved before actual construction begins. Anna and Dan were in the thick of completion of these requirements with Greg’s guidance and although immediately thrown into the deep end, they successfully managed these important first steps. Blueprints and books were strewn about our house all winter as Greg boned up on his building know-how. Not the least of it was Greg learning how to compromise or ‘gently’ nudge when some design, purchase, and scheduling discussions were at an impasse as Dan and Anna were learning to work with him. ‘Gently’ and Greg are what you would say is an oxymoron.

Finally, permits were approved, supplies had mostly been ordered, and with all the ducks in a row Greg headed down to PA a week before me to work with Dan and Anna on waterproofing and insulating the poured concrete foundation as well as set drainage pipe in the basement. I remained home and had one last glorious week of golfing, hiking, paddling, visiting with friends, last minute garden harvesting, and also some packing and errand running for what I expect will be month’s stay.

Monday of week 1 arrived and Greg and I worked at the site while waiting for supply delivery. Sill plates of pressure treated lumber needed to be installed with holes drilled to accommodate the anchor bolts pinned into the concrete walls. On top is another layer of 2×6 lumber and everything is bolted down tightly (N. B. I may omit some details for the purposes of avoiding excessive boredom-trust me, there’s lots more to it). We started assembling the steel beam/Lally columns supports that hold up the house from the basement up. Now comes the nerve wracking part (for me, anyway). Our excavator, Jamie showed up to lift the three sections into place and I breathed a sigh of relief. It actually went very well.

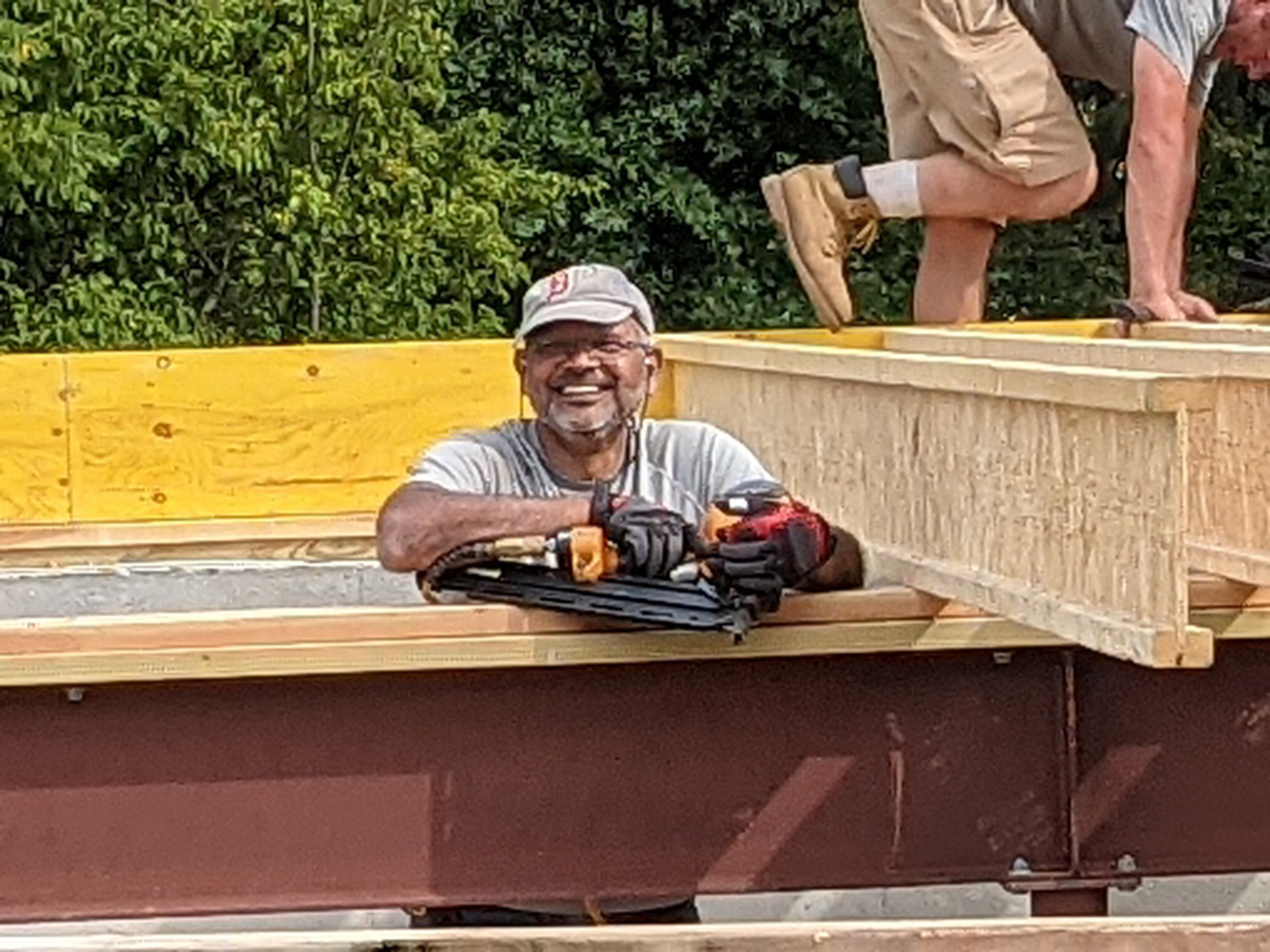

Greg’s brother Bob arrived as well as as our friend Christopher. Dan has 3 days off midweek for each week in August so we have a crew of 5. Greg and Bob, as my sister-in-law Tina and I like to say, are identical twins, in character, born 4 years apart. It is good and reassuring to have Bob’s support; he’s a recently retired engineer (go Buckeyes!), he understands Greg and his process, and has participated in all our crazy projects to date (and likewise, us in his). Christopher is game to help with anything and is a great friend to rely on. He recently moved to Philly, though not for us, but we’ll take advantage anyway. We began setting the I-joists into place, spanning the walls across the steel beams and (mostly) spaced 16 inches on center. (‘I-joists’ replace heavier 2×12’s but provide as much strength or more to carry the load of the floor and walls.) Time is spent levelling the joists from wall to wall and remarkably, the cement footings in the basement and steel structure are mostly level which makes the task easier (but not necessarily easy). And day 2 ends.

Day 3 we start laying the plywood floor, Dan on glue gun, Christopher on framing nailer, and Bob moving the Advantech plywood into place, tongue into groove tightly and straight on the joists. Greg is there to correct any issues since some of the joists are not necessarily 16 inch on center (due to accommodating carrying loads, LVL placements, among other things. (LVLs are glue-laminated layers of veneer or plywood which are used as load carrying beams when steel isn’t required, like for shorter spans). My job is to load the plywood onto the tractor and move it into place (with some help from Dan or Bob). Greg has been ‘tight-rope walking’ the joists and beams then everyone else becomes comfortably settled as the floor slowly expands from side to side. It’s a long day but other than the giant hole for the staircase, we have a floor in place.

It’s been cloudy and not too hot but day 4 is cloudless and getting hotter. And we realize the building lumber for walls that was delivered is the wrong length. This was potentially a major disaster for our timeline as Bob and Christopher are leaving and Dan has to go to work next day, so we’d be behind 2 days at least and would have wasted our crew’s valuable time. Greg made a strongly worded phone call and the correct shipment reached us before lunch as we kept busy prepping for exterior 1st floor walls. Greg marked the placement of the windows and doors, Dan and Bob nailed the 2x6s and headers into place, I delivered lumber to the appropriate location and made the cuts for length as needed. We all lifted and leveled and nailed, wall by wall, until most of the exterior walls were up and braced. But it was freakin’ hot so gallons of water and Powerade and shaded rest were required. Welcome to August in PA.

It’s Friday and it’s just Greg and me. We finished the exterior walls and with Anna joining us on her lunch break we built one interior wall that spans the width of the house. It became too hot to continue to work outside so Greg and I retreated to the basement to finish digging the sewer line to the appropriate grade. Not necessarily an improvement in conditions though we weren’t in the sun. After the usual cleanup: tools put back in the vehicles and tractor, compressor and generator chained up, looking for phones, etc, day 5 ended. Air-conditioning on max, we met up later with Dan and Anna and headed to Rochester for a most excellent family wedding and a much needed break.

We had all developed golfer’s tan: tan lines delineated by short sleeves and shorts and socks despite copious sunscreen application. And who thought this was a good time for growing her hair longer? In any case, we mostly enjoyed the hard work (but not the heat). I’m hoping this experience might serve as a ‘boot camp’ fitness experience though there is no evidence as of yet to support this. In any case, we’ve had a good week with good company, good food (where my fitness plan backfires), and good hard work. Not bad for a crew in their sixties!!!